Overview of pneumatic diaphragm cut-off valve

The pneumatic diaphragm cut-off valve adopts a top-guided structure and is equipped with a multi-elastic diaphragm spring actuator. It has the advantages of compact structure, light weight, sensitive action, S-shaped fluid channel, small pressure drop loss, large valve capacity, and easy disassembly and assembly.

The pneumatic cut-off valve receives signals from the regulating instrument, cuts off, opens or changes the flow direction of the medium, and achieves automatic control of process parameters such as pressure, flow, temperature or liquid level. It is widely used in production process automatic control and remote control systems in various industrial sectors such as petroleum, chemical industry, metallurgy, electricity, light industry, and textiles.

This series of products has two types: diaphragm type and piston type. The valve body structure has three types: single seat, sleeve, and double seat (two-position three-way). The sealing form has two types: packing seal and bellows seal. The product nominal pressure level has four types: PN10, 16, 40, and 64, and the nominal diameter range is DN20~200mm. The applicable fluid temperature is from -60 to 450℃. The leakage level is IV or VI. The flow characteristic is fast opening.

Product features of pneumatic diaphragm cut-off valve

1. The cut-off valve adopts a multi-spring actuator and an adjustment mechanism connected by three columns, which can reduce the entire height by about 30% and the weight by about 30%.

2. The valve body is designed as a low-resistance flow channel with equal cross-section according to the principle of fluid mechanics, and the rated flow coefficient is increased by 30%.

3. The sealing part of the valve trim has two types: tight type and soft seal. The tight type is welded hard alloy, and the soft seal type is made of soft material, with excellent sealing performance when closed.

4. The balanced valve trim increases the allowable pressure difference of the cut-off valve.

5. The bellows seal type forms a complete seal on the moving valve stem, blocking the possibility of medium leakage.

6. The piston actuator has a large operating force and a large pressure difference.

Main parts materials of pneumatic diaphragm cut-off valve

Valve body, sealing sleeve: HT200, ZG230-450 ZG1Cr18Ni9Ti ZGOCr18Ni 12M 02Ti

Valve core, valve seat: 1Cr18Ni9Ti OCr18Ni 12M 02Ti 1Cr18Ni9Ti surfacing Stellite alloy

Sleeve, valve plug: 1Cr18Ni9Ti OCr18Ni 12M 02Ti 1Cr18Ni9Ti surfacing Stellite alloy

Padding: polytetrafluoroethylene, flexible graphite

Corrugated diaphragm: nitrile rubber sandwich reinforced polyester fabric

Spring: 60Si2Mn

Valve stem, push rod: 2Cr13, 1Cr18Ni9Ti

Valve core, valve plug (soft parts): reinforced polytetrafluoroethylene

Bellows: 1Cr18Ni9Ti

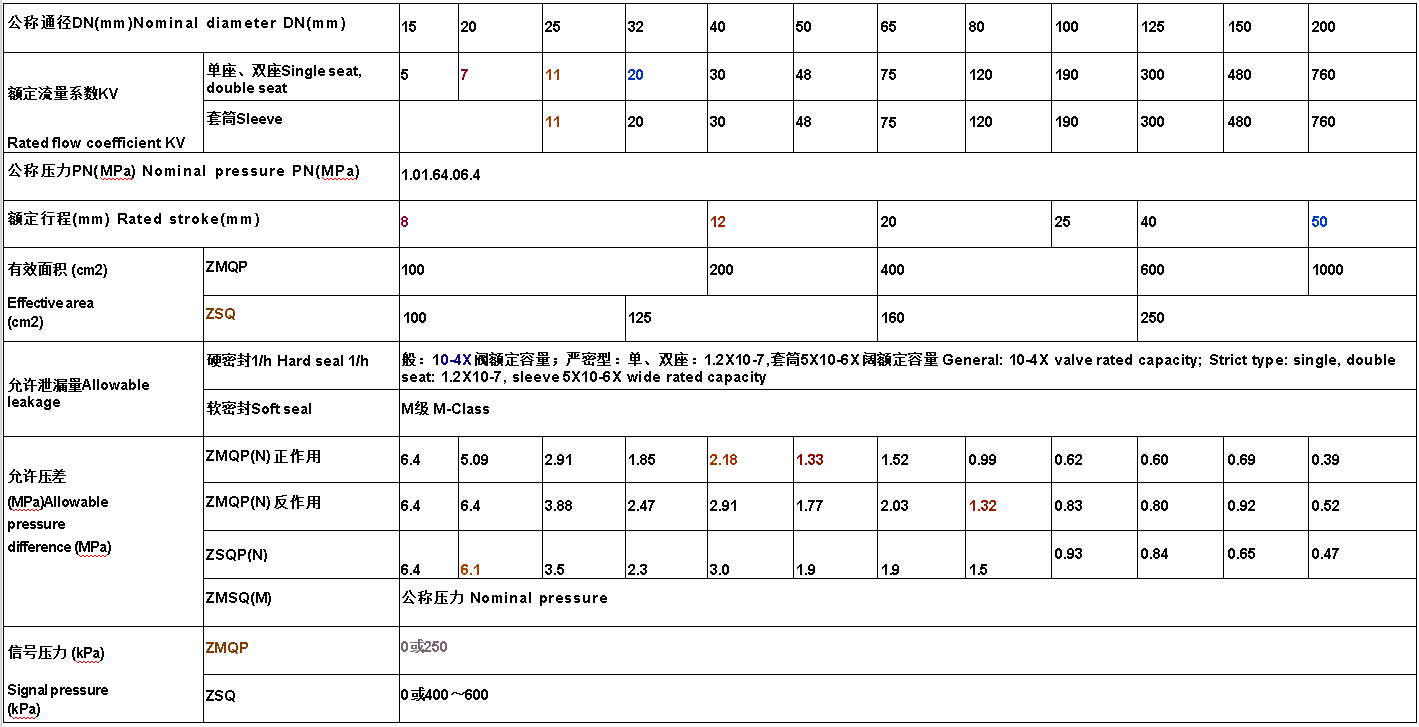

Specifications and technical parameters of pneumatic diaphragm cut-off valve

1) The performance indicators of this product are in accordance with GB/T4213-92;

2) If the allowable pressure difference value in the table is greater than the nominal pressure, the nominal pressure value shall be used; if it is less than or equal to the nominal pressure value, it shall remain unchanged;

3) The allowable value in the table is the value using the standard cylinder, and different cylinders can be used to increase the allowable pressure difference.